Badlab Phase II

Share

Executing the vision one step at a time.

Those who are close to me will tell you that I had talked about this exact moment in time in the Badlab on day one. However, there were some steps that we had to take to make it to this point. I swore on day one that I would take this side hustle on with the basic tools I had always used and built with before, really putting some time and money into how I envisioned the way we operated on a day-to-day basis, simply put, we had to build up some momentum and a small following first, the business also had to pay for itself rather than continue to be a money pit like it was for our first 12 months of the ground.

If you were here on day one, you are my brothers' keepers.

I bit my lip every time I was asked for flat packs and acrylic work, as I was not going to be able to simply send out any Joe Blog's flat pack or be able to outsource acrylic work and engraving that would be cost-effective to make any kind of money, let alone break even.

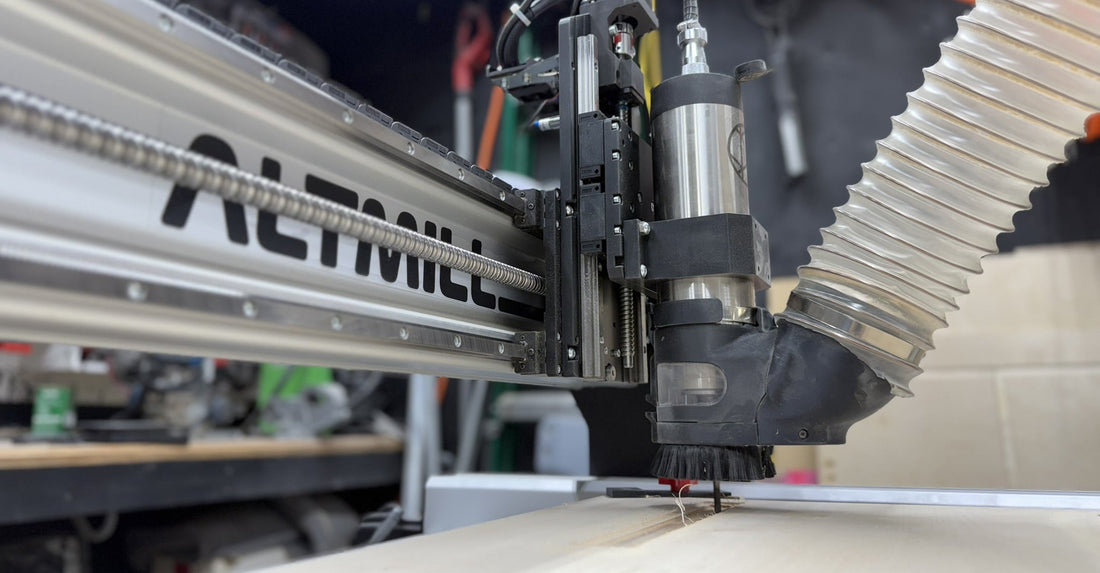

To do this and be great at it, I had to switch gears with the business and pull the trigger on layering in a CNC machine to the business. this was what we had been working towards since day one, and the time had finally come. This part gets a little crazy because buying a CNC actually isn't that expensive; it's setting your work area up to accommodate it, where it starts to really test your nerves. Dust collection is the pinnacle infrastructure needed to layer in, to make your work area safe and efficient.

We will save the fine details for another blog post, but after doing months of research on what would work best for what we needed, the Sienci Labs Altmill 4x4 mkII, was going to be the best route with the space I had available in our small shop. This robust workhorse has exceeded our expectations, and it has crushed a lot of the worries I had about owning and running one for several hours a day.

This is where buying a $3500 CNC turns into a $10,000+ exercise by the time you layer in the dust collection, spindle kits, software, router bits, loss in material while you learn how your machine runs and make rookie mistakes creating the toolpaths. If you think that this is chump change because box builders make bank and live lives of luxury, I highly recommend finding out for yourself (facepalm emoji here) you will be let down...

In addition to layering in the Altmill we had to get serious about sourcing quality 3/4" (18mm) true Baltic Birch hardwood (BB) and make it the primary material used in all production going forward, This has been a challenge for me being in NELA, simply put it's just not available local to me, but like always, nothing motivates me more than overcoming something that is not easy.

With the added commitment in our production costs between running a CNC and stepping up to the best quality build material you can buy, it has driven up the costs of your average build just a touch; however, the quality difference has out-run that additional cost by leaps and bounds.